Sometimes, they return...

- Written by Mauro Errico

Concrete laying surfaces: years go by but the problems remain the same. Here are two examples of how NOT to do things.

There are days in which I really fail to understandwhy - even aftermore than two decades of seminars, meetings, andmore than ample technical presentation – I keep encountering the same problems again and again. Many people working in the construction business, who in my opinion are often unprepared, resolutely continue making the same mistakes, even if the correct technical information is copious and has beenwidely diffused throughout the nation: just consider how much money the leaders in the sector have invested in research and the distribution of technical documentation, videos, and brochures. As the Latin poets were fond of saying, perseverance in error is diabolic, butwhen facedwith certain problems, the entire body of technical knowledge seems to be no use at all to these people. Below, I describe situations that I examined in two different work environments in two geographically distant in which the final result was practically the same. In both cases, fortunately, the parquet installer assigned to the job proved to be sufficiently scrupulous, and raised his objections regarding the quality of the laying surface right from the start. These parquet installerswere undoubtedly dismissed as “fanatics”– as usual – but the final client forced to suffer the initial inconvenience, proved capable of solving the problemwithout increasing the damage. Let’s take a closer look at both cases in question. The first case: analyzing the screeds prior to laying My first technical inspection regarded the structures of a few self-leveling concrete screeds laid in a number of apartments for a total 600 m² surface area at a newbuilding construction site. Screed examination overview I analyzed the rapid hardening self-leveling screeds, which consisted of a floor slab and embedded underfloor heating systems. Around fourmonths had passed fromthe final casting of the screeds by the time I arrived. The Director of Works had informedme that their thickness varied from a minimum 3 to a maximum 8 cm. Measurements had been taken starting from points just over the heating systems. Metal reinforcementwebbing –without expansion joints – had been embedded inside the screed, especially near the “doors”, which are usually the areas of the room with the greatest variations in dimensions. For this type of screed, the surface area that should ideally be coveredwithout interruption is usually around 40 squaremeters, and so-called expansion joints are always created near door thresholds. My first visual inspection revealed the following anomalies in all the apartments with screeds already laid:

- whenever anyonewalked over them, some areas of the screed gave off a dry thump and flexed downward (relatively large areas of screed weremoving up and down);

- noticeable differences in levelwere also observable in these areas;

- the surfaces of the screedwere fairly “brittle”; in otherwords, the cementmixwas not compact, and so crumbly that it was immediately evident;

- noticeable cracks had formed near the thresholds of the doors, in particular.

The Project’s General Specifications included the laying of a solid wood floor by gluing in every part to be completed on site. The scruples of the conscientious parquet installer As luckwould have it, the parquet installer assigned to laying the floor was suspicious of these anomalies, even if the main contractor urged him to meet the deadline nonetheless. In order to get a better idea of its characteristics, I examined the technical data sheet of the rapid hardening self-leveling screed used.At the start of my technical inspection, I had tried to take a few samples of the screed without success due to the compactness of the cementmix, which was, in fact, so brittle that taking samples was impossible. The causes revealed Following other inspections and checks using the test instruments required to obtain a more complete picture of the laying of awood floor, themain and the contributing causes responsible for the various anomalies observed were identified as:

- “Screed areas that give off a dry thump and flex downward when walked on” This situation that was observed in all the rooms, especially in the areas nearwalls, can be ascribed to an “accidental” penetration of liquid cementmix beneath the heating panels. This infiltrationmight have been caused exclusively nearwallswhere the edges of the paneling had not been correctly “sealed”. This allowed the self-leveling cementmix to penetrate beneath the panels, in this way swelling up. During the moment of compression caused by the passage of people, these portions sag and cause those dry “thumping” sounds and the downward flexure of corresponding portions of the screed. As may be seen in the photographic documentation provided, it is clear that this penetration can go directly to the floor slab in the perimeter area (the panel does not reach the wall and no cement mix container barriers exist).

- “Differences in level” Differences in level are a consequence of the infiltration described above, and are, in fact, observed exclusively near the perimetral walls. In this point however, itmust be specified that precisely due to their failed adhesion to the support floating screeds or screeds with sheets of PVC or other insulation material may undergo deformation caused by their shrinkage. Bearing in mind the content of the description provided in Point 4 below(very rapid surface drying), the screed may have assumed a concave shape (the screed rises up at the sideswith the creation of empty spaces below; see the figure above), which when subjected to loads (walking) breaks, or in other words, flexes even further downward.

- “Poor surface compactness and brittleness of the cement mix” These two problems share the same cause, or in otherwords, the excessive quantity ofwater used for the concrete mix. The product’s data sheet refers to 4 liters per sack for the working of the freshmortar. The analysis of the cementmix as being overly brittle allows us to statewith reasonable certainty that the causemay be ascribed to quantities ofwater higher than the recommendedmaximumlimit. Consequently, superficial mechanical resistance decreases exponentially. After 28 days, an average compression resistance of approx. >5N/mm2 should be obtained, if not the surface of the screed “crumbles easily”.

- “Gaps and cracks” These were not just the tiny fissures that occur normally when the cement mix shrinks but rather authentic “cracks” caused by inhomogeneous shrinkage.

Gaps and cracks were due to both the presence

of toomuchwater and the excessive exposure

to ventilation of the surfaces in question

while the cement mix was drying. Although

producers’ recommendations include

providing the cement mix with protection

against draughts of air for at least the

first 48 hours, in realitywe can cut that time

down to 24 hours, but in such case the surface

must be provided with absolute protection.

At the worksite in question, the external

door andwindowframes had still not

been installed even at the moment of our

technical inspection, and as stated by the Director

of Works himself, the building’s external

openings were not even minimally

protected by nylon tarpaulins or other material

during the mortar casting phases.

This led to the overexposure of the screed’s

surfaces to excessive ventilation precisely

during those crucial initial hours of cement

mix hardening. In this regard, the “waves”

in the screed’s surface provide the proof of

this excessive “ventilation” during drying.

The lack of joints of any kind and the evaporation

of the excesswater led to the shrinkage

observed in the cement mix producing

these phenomena of “excessive shrinkage”

that may be seen along the lateral walls in

particular, as is clearly shown in the photos.

Asmeasured and verified, the entire screed

execution processwas clearly spoiled by the

presence of evident anomalies ascribable to

the working of the material.

During various discussions with the other

people present during the inspections –

with the exception of the Director ofWorks

– another detail emerged that has a lot to

show about certain problems involved.

The company that formulated the cement

mix for the screeds had rightly stated that it

had no previous experiencewith this type of

material, and for such reason had requested

the presence of personnel fromthe product’s

supplier.

Unfortunately, as confirmed by the facts, the

technical instructions provided during operations

to themen assigned to actually laying

the screedswere not sufficiently helpful.

If what I was told is true, to the extent that

I could hardly believe my ears, the quantity

ofwater used should absolutely have been

controlled better, instead of advising the

workers to addmore, as these technicians effectively

did, without adequately monitoring

the workplace subsequently and providing

it with at least the minimum protection

against gusts of

wind.

At any rate, the damagewas

done, and the

question of how to recover

the screeds for

the purpose of containing

the costs required

for the recovery

of the rest of thework,

which could have been

very high, given the

presence of climate

control systems with

panels embedded into

the cement mix was

not an easy one to

solve: the “cracks” had

to be previously filled,

and this required them

to be widened in “V”

shape by inserting iron

bars and then filling

the space createdwith

the appropriate substances

available in the

market. The self-leveling

screeds also had

to be subjected to a restarting

cycle of the

radiating heating systemas

specified by the

standards in force in

the sector (UNI EN

1264-1/2/3/4) and the

entire cycle had to be

brought to completion.

This operationwas not

only absolutely advisable

but inmy opinion

indispensable, also because

the structural situation

of the screed

could have led to further

shifting and crumbling

of the cement

mix in addition to additional

cracks caused

by shrinkage.

The second case

In the second case aswell, the purpose of the

technical inspection conducted in an apartment

complex located in a historical big city

™centerwas to evaluate the condition of the

laying surfaces in traditional concrete cast expressly

to underlie a solidwood parquet floor

to be laid by total gluing.

Once again, the analysis wasmade by visual

method using a few manual instruments

over a total cemented surface area of around

85 m2 on one of the building’s floors.

Aceramic floor had already been laid in the

two bathrooms, while in the rest of the

house (foyer, living room, kitchen, and three

bedrooms), a solidwood floor in herringbone

pattern - an element of notable prestige

and quality - was scheduled to be laid.

Structural problems

Because thewood floorwould be laid by total

gluing using a synthetic adhesive, the

structural investigation of the laying surface

was conducted by bearing in mind the contents

of Standard a UNI 11371 dated September

2010 Wood and parquet flooring

screeds – Properties and performance characteristic.

According to the Director ofWorks,

the screed had been cast approximately

threemonths prior to the laying of the floor

but an instrumental check revealed that a

moisture content ofmore than themaximum

permissible 2% remained.

Furthermore during destructive testing, aggregates

of hygroscopic nature had emerged,

in other words, lightening materials, presumably

expanded clay; unfortunately however,

the company that had laid the screed

had not documented its composition. Investigation

also revealed that no vapor barrier

has been inserted, and that the cement

aggregatemixwas absolutely brittle and inconsistent.

What’smore, after the spreading

of the concrete casting, the worker decided

to also apply a layer of self-leveling agent

over the surface of the screed that upon our

inspection appeared to be clearly detached

from the latter.

It was obviously impossible for us to learn

theweight of themoisture content before the

self-leveling agentwas0 applied, but seeing

the detachment that occurred,moisture levelsmust

undoubtedly have been high in the

laying surface. Stress tests demonstrated

the presence of extended areas of self-leveling

agent that had already detached fromthe

surface of the screed, most certainly due to

the different hygroscopic shrinkage coefficients

of these twomaterials,which definitely

compromised the possibility of laying a

glued parquet floor.

During inspection, the concrete screed laid in different rooms presented an evidently irregular

and compromised structural situation.

These problems leave little room for

doubt. Furthermore, on thewhole, the screed

did not even partially possess the performance

characteristics summarized in Paragraph

4.2.2. Page 4 of UNI 11371:2010.

Lastly, the presence of hygroscopic material

in the cement mix compromised the time

required to reach a residual humidity value

appropriate for parquet (2%), and the complete

absence of a vapor barrier only made

thingsworse . For this reason, in this case as

well, as far as we were able to ascertain and

measure, formed as itwas, the screedwas inadequate

to underlying a glued wood floor,

also because it presented defects that precluded

its recovery even through the use of

other products.

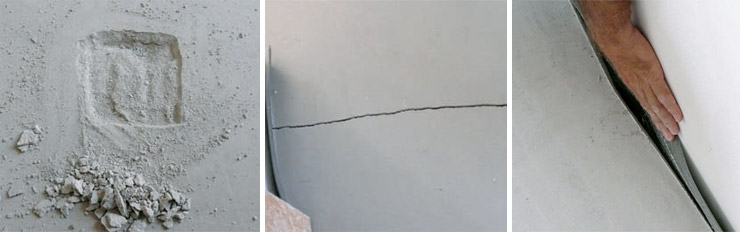

The photos show some of the problems observed during inspection: differences in level, brittleness, and cracks.

Starting all over again

In this case, the laying of the parquet floor onsite was possible only by completely dismantling the existing laying screed and redoing it all over again, naturally after first checking the thicknesses remaining after removing the screed and choosing a product suited to its new formation, ideally a quick hardeningmaterial capable of shortening the execution times that had already been extended far too long. As may be seen in the photos, it is simply amazing that such brittle and inconsistent screeds could be laid, without even going into the question of the absence of the vapor barrier, a function that appears to be entirely unknown tomost people when instead it is just another simple product that can be very useful in the success of their day to day work.

These photos were taken during the second inspection.