When wood meets technology

- Published in Technology

- Be the first to comment!

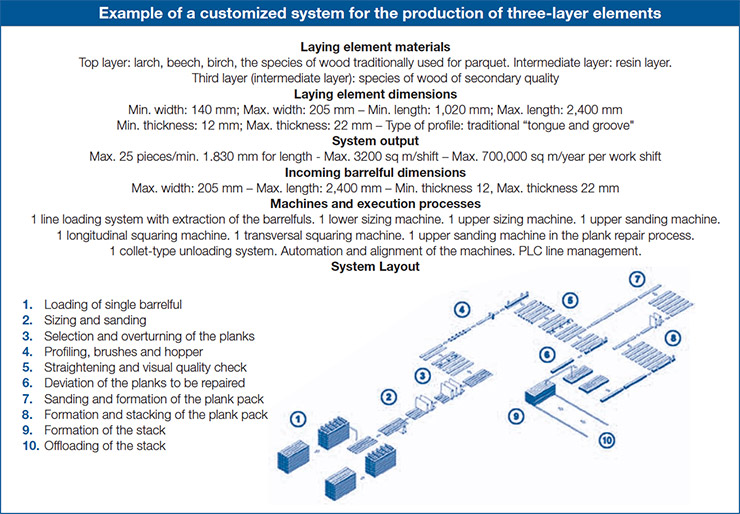

Flexible automation and robots for the production of multilayer parquet elements.

Avisit to the latest edition of the “Xylexpo

2014” Show dedicated to the

woodworking machinery sector last

May at the Rho Trade Fair Grounds in Milan

provided ample demonstration that the

time has come to go beyond rigid, fossilized

processes in the direction of newproductive

structures that have higher flexibility in

mind. The final blow to Traditionalism was

recently given by many companies, especially

those based in Asia who have made

Just in time programming their winning

card. The market has changed radically

again, even in just the last fewyears, and the

merciless competition fromcompanies producers

in the developing world has obliged

many parquet producers to choose systems

that are capable of providing rapid response

to variations in client demands.

Reducing times and costs seem to be

the factors to bear in mind in the

newtechnological processes, and

multilayer parquet (erroneously

often referred to as pre-finished)

is not excepted from

these new commercial dictates,

and for this reason products

now tend to be completed

only at the moment of

shipment to the client.

The advantages derived

are excellent because reduced stock levels require lower capital investment.

This latest edition of the XylexpoShowalso

demonstrated thatmostwoodworking

systems and machines have been

computerized by nowand computers permit

the management with rapid flexibility of

more economical production lots controlled

by programs with such simple instructions

that they can be programmed by anyone

with a minimum amount of training.

The robotizing of certain processing phases

bywork centers and logistic systems has also

rendered processes for both solid single-layer

andmulti-layer parquetmuchmore flexible

and economical. Robots are mechanisms

that repeat a number of elementary operations

and therefore raise output. Their

widespread use has played a key role in increasing

industrial automation.

The Cartesian, hybrid, and anthropomorphic

robots presented at Xylexpo 2014 by many

Italian and international companies vaunt a

reliability that has by now been guaranteed

by international regulations. The “automatic

factory” is already on the horizon in the

foreseeable future, and nowmany companies

even in the Orient can offer CIM (Computer

Integrated Manufacturing).

The advantages of automatic cutting-off machines

The multi-layer parquet adventure begins

with the planning and cutting-off of the solidwood

performed on high-quality systems

appropriate to every productive need. Automatic

cutting-offmachines comewith optimizers

that reduce scrap to aminimum, and

companies with high productions use excellent

cutting-off lines with ideal optimizers

that are quick and easy to use (less than

0.002 seconds for all cutting calculations).

The conveyor reaches elevated speedswith

extremely rapid accelerations and cutting

times, while the possibility to obtain different

sizes by means of a simple selector

suits the cutting-off machines to any need

the client may have. There are also cuttingoff

machines at the technological vanguard

for optimized cuts with translation rollers

suited to every size (unworked or deformed) with advance speeds of up to 240 m/min. and width/length readers that provide a

summary of the volumes cut.

The choice of the cutting-off machine depends

on the maximum section of the solid

wood to be cut. Automatic lines require no

specialized operators and offer constant

output, whereas optimized lines ensure

higher efficiency (less scrap and higher productivity)

than automatic

lines.

Cutting-off machines

with optimizers are

commonly used to

eliminate waste and

accelerate the cutting

of the more valuable

species of woods, but

their exceptionally

high speed and output

permit their use also

with types of wood of

lesser value.

Defects are displayed

either by automatic

scanners or by lasers

maneuvered by the

operator, and can by

driven by roller, by

belt, and by pusher

bar. Disks of 550 mm

diameter can be used

for cut-offs on solid

wood up to 800 mm

wide and 25mmthick.

For productive cutting

Lathsor fingers formultilayer

parquet can be

cut by disk or by blade

on multi-blade sawing

machines, whereas the

topandbottomsurfaces

of the lath are already

suited for immediate

gluing.The cuttingunit

has centralized electronic

control that ensuresperfect

cuttingprecisionwith

aminimum

amount of play (0.1

mm) andfeedspeeds of

up to 20m/min.

The use of hacksaw

blades provides higher

output (20%) than

traditional processes,

and even permits the cutting of laths from

moist wood that is required when two or

three layersmust be glued togetherwith high

frequency.

The laths and boards for parquet to be cut

with boxed blades can be obtained from

boards that have been cut-off andworked on

three surfaces (using a lateral or central

ruler) or on four sides (with guides in the raceways. Both laths and the smaller boards

can be sizedwith tool-holders positioned at

the end of the cuttingmodulewith up to 0.05

mm precision. Wood laths can be cut to a

minimum3mmthickness using 1.1mmtools

in satellite (a cobalt-chromiumalloy) for significant

increases in productivity.

Whereas bladed cutting unit feed speeds can

reach 2 m/min., disk cutters can reach 36

m/min. with 1.2 mm thickness and the

possibility to have a lower engraver of just

1.1 mm. This results in a 20% higher output

in the production of multilayer parquet,

and the machine tools used by now all possess

planing work centers capable of sizing

the boards on all four sides with the possibility

to obviously insert unworked smaller

boards in the line.

The lath technique

Automated processes are capable of beginning

theworking of the solidwood board by

planing it and transforming it into laths, and

then pairing, pressing, and drying them

continuously. The boards are dried in vacuum

cells with or without heating plates.

The former technology is used in cylindrical

vacuumcells in which the vacuumnot only

dries but also applies 10 ton sqmpressure on

the solidwood boards for further advantages

to the quality and speed of the process.

The processwithout heating plates is adopted

both in cylindrical cells and parallelepiped

cells with continuous or discontinuous vacuumandwith

hot air ventilation; this system

is best suited to making stacks of strips of

wood. The market offers vertical saws designed

for the top layer ofmultilayer parquet

that can be inserted in production lines

composed of a lath loading area (with obligatory

identical width, whereas the length

may be variable), followed by composition

and subsequent gluing areas. In the final step,

an assembly and drying area provides one

single and continuous plank from which

compositions of plank of equal size can be obtained

fromlaths in two, three, or four rows

as required by themodel ofmachine utilized.

The newlines for the gluing of the single layers

of themulti-layer element to be laid in two

or three layers utilize polyurethane adhesives

spread at 120/140 °C or vinyl-based adhesives

(70-80 °C) in order to assembly solid and

not invulnerable to environmental deformation.

The adhesive is applied in molten

form on the layers to be pressed together,

while the production of the three-layer element

can also usemelaminic adhesive due to

its better resistance to chemicals and water.

The bonded layers consist of obviously the

noble wood top layer (3 - 6 mm thickness)

and the other two or three layers of less noblewood

species or strips of plywood (from

5 - 10 mm thickness). The adhesive between

the solid wood multilayer element’s

layers can be made to dry quickly using a

high-frequency system by adjusting the

power in successive stages (12 positions) and

with ceramic triodes.

Not only the finish

Mostworthy of note among the profilingmachines

and squaring machines that have by

now become totally automated are those

(whetherwith traditional tongue-and-groove

or on-edge snap fit)with 110mmtool-holder

shaft length and feed speeds of up to 70

m/min. suited for the production of parquet

with variable width of from 65 to 400 mm

and lengths of up to 4m. There are also combined

planing-sanding units that permit

the dead times that usually occur between

these traditional processing phases to be

eliminated. As regards parquet logistic

equipment, various automatic feeders, loaders,

and unloaders capable of forms packs of

strips for subsequent working could be admired

at Xylexpo 2014.

The alternative to varnish that consists in the

heated coating of the multilayer laying element

surfaces in just one single passage performed

continuously eliminates a number of

stages in the traditional process (puttying,

sanding, application of the primer and sand ing), thereby shortening finishing times

enormously.Many products by nowhave elevated

UV radiation stability, excellent impact

strength, optimumhardness, and good

chemical resistance. These products are applied

liquid using a pre-heater and then solidify

at roomtemperature. These short narrowstrips

require three or four days of storage

before they can be profiled, however.

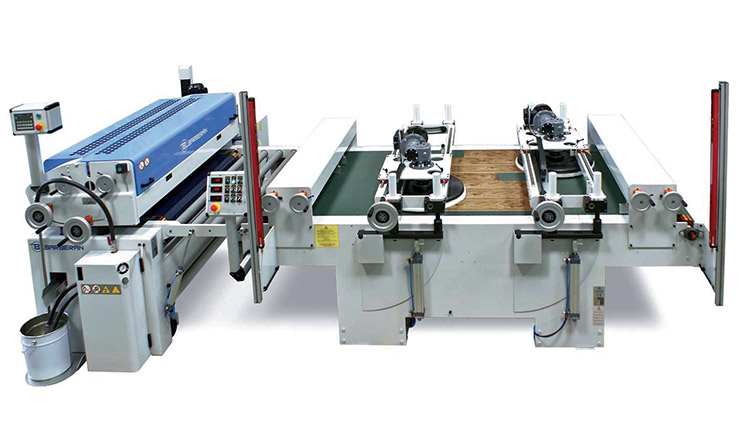

The world of varnish

For those who use traditional processes,

water-based varnishes – the only ones with

respect for the environment

– have been

available in themarket

for quite some time

now, even if they have

often been overshadowed

by solvent-based

products that are easier

to sell. Painting systems

are designed on

the basis of the type of

paint and finish desired

by parquet producerswhile

also bearing

in mind the possibility

for light or heavy

staining.

Despite the fact that

application and drying

systems and cycles

vary widely, there are

also versatile polyvalent

machines capable

of being quickly and

easily set up for the

desired type of finish.

One multilayer parquet

element varnishing

process that is being

adopted all around

theworld utilizes three

coats of primer applied

by roller, each of

10 g/sq m thickness.

The process consists

of an intermediate

semi-polymerization,

a final polymerization

with a subsequent intermediate

sanding

followed by two finishing

coats applied

by roller of 10 g/sq m

each,with an intermediate

semi-polymerization

and a final UV

polymerization. The

system can have minimumwidths

of 30 cm.

and the machines used include: lacquering

machinewith standard rollers (providedwith

applicator roller and dosing roller with

three separate commands that permit the

dosing roller to rotate in opposite direction

whenever minimum applications are required),

UV-module driers (that polymerize

varnishing products in just a fewseconds, to

which photoinitiators are added) and intermediate

sanding machines (used to

smoothen the surface with primer and prepare

it for the application of the finish).

The technology behind UV paint products permits elevated output and permit the use

of minimumweight formats with noteworthy

savings of material.

Paint and varnish producers have by now

specialized and diversified their products by

type of finish and by cycle. This means that

acrylic- and UV polyester-base primers and

finish coats formulated for extremely short

cycleswith high abrasion resistance and excellent

adherence and elasticity can now be

found in the market.

Conclusions

The productive process future, which will

most likely be based on automatic fabrication

with CAM(ComputerAidedManufacturing)

and CIM (Computer Integrated Manufacturing)

management keeps getting closer and

closer. It is also an accepted fact that robotizing

certain processing phases, innovative

work centers and logistic systems combined

with more and more flexible and personalized

productive cycles and processes will

provide considerable advantages in both productive

(shorter and shorter fabrication

timeswith higher and higher output and efficiency)

and economic (lower overheads and

rationalized resources) terms, in addition to

greater abundance of the offer. In my opinion,

all this should not lead to standardization

but rather the contrary: the objective and

real possibility of access tomore innovative

single devices, machines and production

lines should stimulate entrepreneurs to improve

the quality of their products.

Even if they are elementary in form, the above

is always the result of a specific project that

through a precise and analytical technical-productive

procedure that permits the discovery

of personalized solutions by involving the

company first and foremost of all. These are

the forms of personalization that characterizemultilayer

parquet andwood flooring elements

thanks to the quality of the tools,

equipment, machines, systems, and lines

that permit the fabrication ofmillions andmillions

of laths, boards, planks, and maxiplanks

for every taste, every day.